Surfacelogix

Rapid Cure MVB Tinted - Epoxy Primer & Moisture Vapor Barrier

Rapid Cure MVB Tinted - Epoxy Primer & Moisture Vapor Barrier

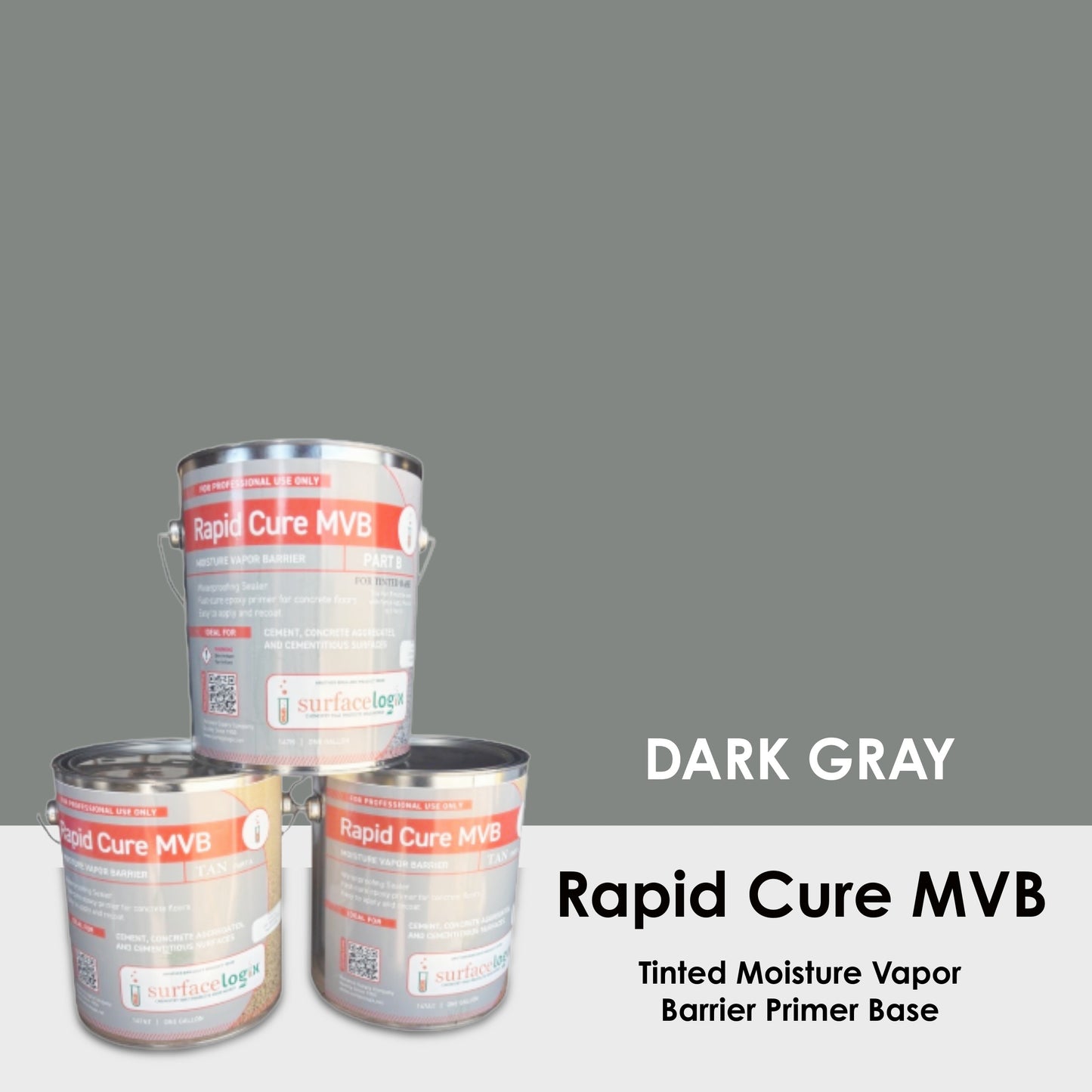

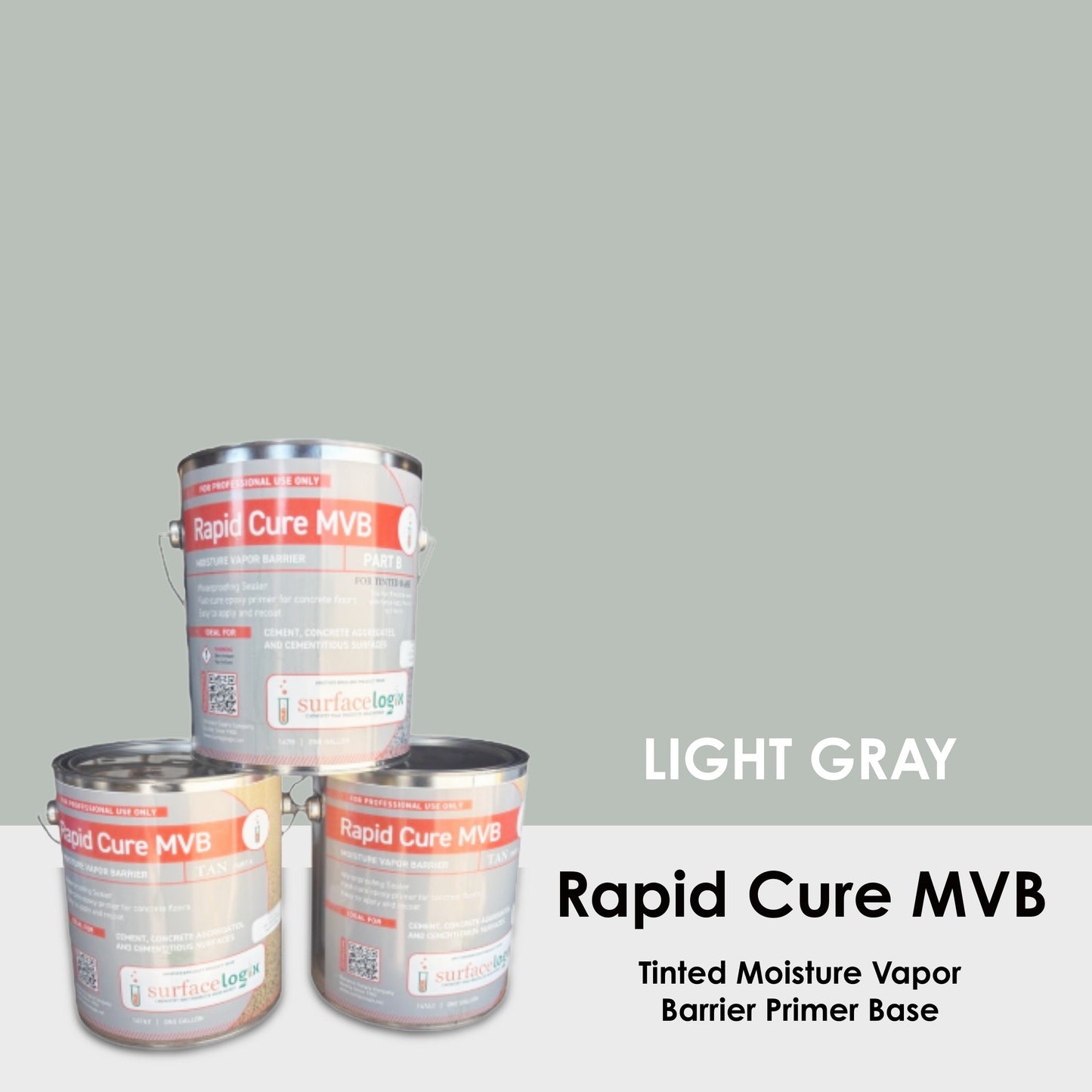

Rapid Cure MVB Tinted Base is an all-in-one moisture vapor barrier, primer, and pigmented base coat designed to protect concrete surfaces from water vapor transmission. This low-viscosity, VOC-compliant, two-component system penetrates and seals the substrate, creating a durable barrier that reduces moisture-related issues such as coating failures, blistering, or delamination. Available in several popular colors, Rapid Cure MVB Tinted Base is compatible with broadcasting flakes and can be sealed with a topcoat of PolyGuard85 Clear. Rapid Cure MVB Tinted Base is a two-component system and is available in 3-gallon kits, which include two gallons of part A and one gallon of part B.

A transparent version of Rapid Cure, Rapid Cure MVB Clear, combines the moisture vapor protection of Rapid Cure MVB Clear with a tinted base color that’s compatible with broadcasting flakes.

Note: Do not apply on pavers or very porous substrates. For professional use only!

Product Features

- 90% Solids & Low VOC

- Commercial Grade

- Low Odor

- Easy to Apply

- High Gloss Finish

- Excellent Chemical Resistance

Applications

- Garage floors

- Restaurants

- Service areas

- Countertops

- Wood

- Laminates

Directions

Preparation: Surfaces must be clean and free of any contaminants before application (oils, grease, or solvents should not be present). New concrete should cure at least 28 days before applying. Rapid Cure MVB’s performance is directly related to how thoroughly the surface is prepared. When applying directly on old concrete or stripped cement, all cracks should be eliminated. Sand/ grind thoroughly with 60-grit sandpaper or diamonds (diamond grind or shotblast to a CSP 1-3 surface profile) and clean off existing coating to provide proper surface profile before applying.

Mixing: Start by mixing Parts A and B of Rapid Cure MVP. The correct ratio of 2:1, as provided (i.e. 2 gallons of Part A to 1 gallon of Part B). Pour Parts A and B into a clean, dry container and gently mix with a drill for 2-3 minutes, avoiding creating air bubbles. Do not mix in a plastic container, as combining Parts A and B can result in a high exothermic reaction, leading to a temperature increase. Always test the product in an obscure area to ensure desired results. Do not apply over clear acrylics, clear water-based systems, pavers, or very porous substrates.

Applications: Apply mixed product at a spread rate of 100-150 sq. ft. per gal. using a squeegee and back roll with a non-shedding 3/8” nap roller to achieve a 12-15 wet film thickness.

READ LABEL THOROUGHLY BEFORE APPLYING PRODUCT

Resources

Technical Data Sheets

Safety Data Sheets

Share

Important Notices

Important Notices

READ LABEL THOROUGHLY BEFORE USING PRODUCT.

CONTACT US WITH ANY QUESTIONS.

Subscribe to our emails

Subscribe to our mailing list for insider news, product launches, and more.